Prototype Flax VE Paddles

Posted on Monday 25th November, 2013

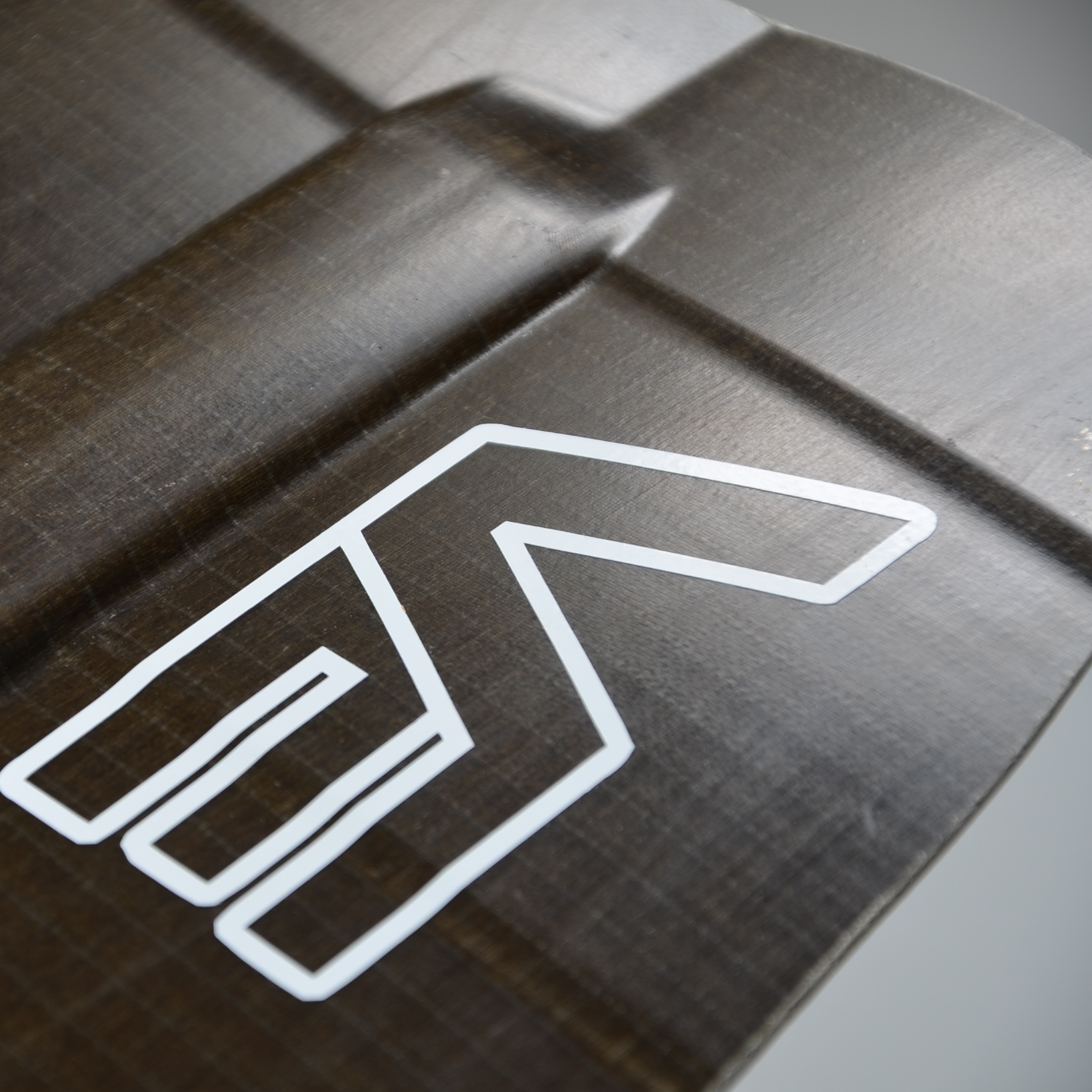

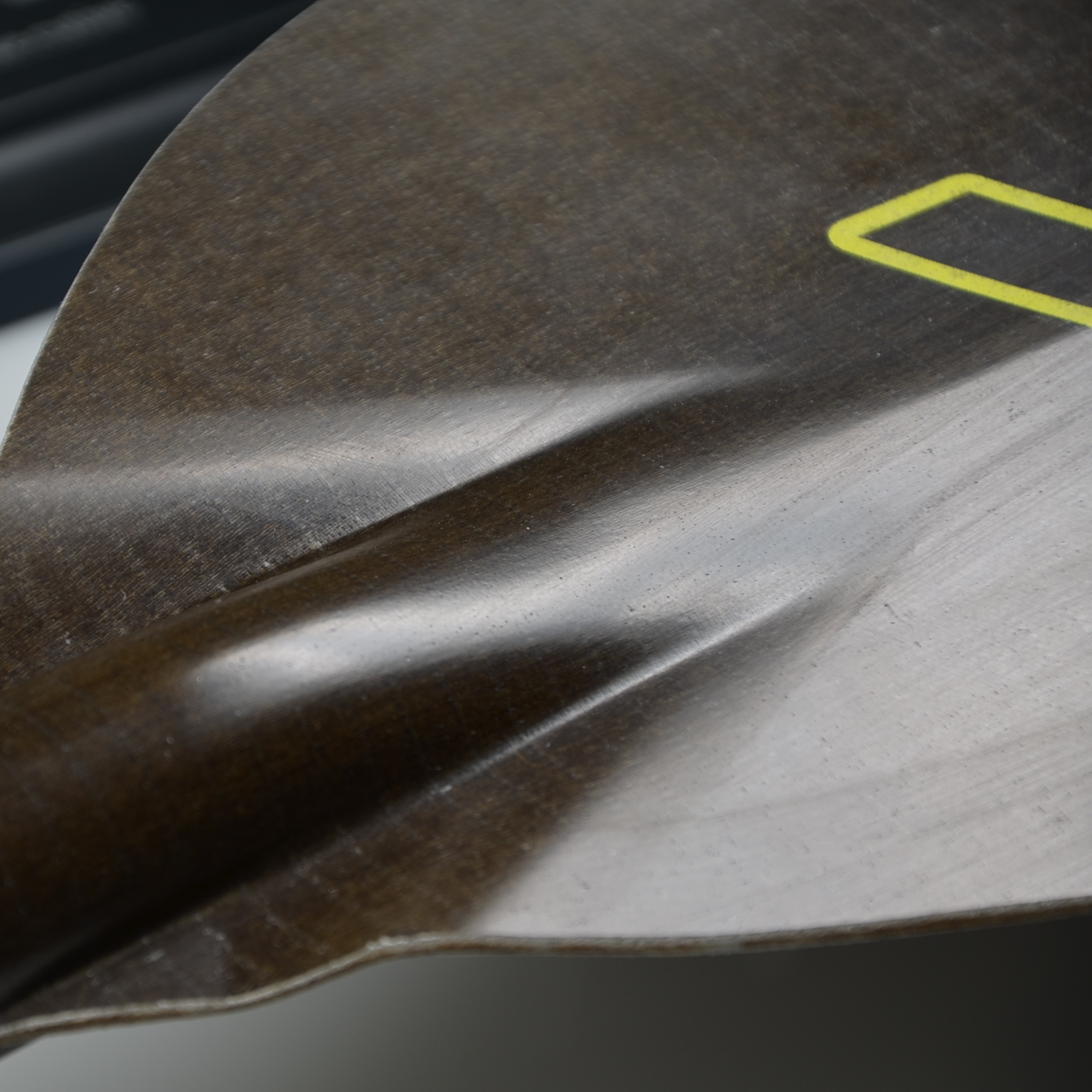

Flax composite paddle by VE Paddles using Bcomp's Flax Composite.

We at VE Paddles are known for our innovation. We recently teamed up with Bcomp and Mathew Morrisey to develope a kayak paddle blade made from flax.

Mathew Morrisey explains more:

Natural fibres have long been used in composite materials: in 1942 Ford won a patent for a plastic car chassis utilising a plastic reinforced with a mixture of pine, straw, ramie and flax fibres; the infamous Trabant body was made from recycled cotton waste reinforced polyester, and more recently, Lotus revealed their own hemp composite based ‘Eco-Elise’. Every year, the European automotive industry uses more than 100,000 tons of natural fibres, primarily in the production of interior body panels.

As a kayaker and materials researcher, I had often wondered about the performance of a kayak paddle made from a natural fibre reinforced composite material. I contacted Christian Fischer at Bcomp, a Swiss company who specialise in natural fibre composites for applications such as snow sports, bikes, and kite boards, and Dr Stuart Morris, a UK-based designer and manufacturer of kayaking paddles.

Both parties were really interested to create a paddle from natural fibre composites. It was agreed to produce a 100% flax-reinforced blade on a standard fibreglass-reinforced shaft. After only a few months Stu had already got to grips with the techniques and procedures required for the new material and produced the first prototype. Bcomp took the paddle to the 2013 Paddle Expo in Nürnburg where it received a lot of interest and survived its first test of being prodded, poked, and enthusiastically flexed by curious attendees.

With low river levels in Switzerland (and the ski slopes already beginning to open), the paddling season has drawn to a close in Switzerland. On apparently the last sunny day of 2013, I took to the Bodensee in a sea kayak to give the paddles their maiden voyage. First impressions are really positive: I was worried the paddle would seem flexible in comparison to a regular composite blade, but the paddle feels stiff and responsive, easily as stiff as a fibreglass, if not carbon, blade. Interestingly, the flax paddle is also slightly lighter than a standard fibreglass model. The blades also have a really unique and beautiful look. This ‘natural’ look and flax’s eco-credentials will certainly appeal to a certain type of consumer.

A final note: flax, like kevlar and aramid, is notoriously difficult to cut (requiring special, super sharp shears). For kevlar and aramid, this translates into unparalleled durability – it will be interesting to find out if this is also true for flax. Let’s see how they hold up to real white water use next season!

Recent Posts

- Avoid the walkout – why everyone should carry a breakdown paddle - March 2024

- The Fara and Vanda – new lightweight touring blades - December 2023

- Fara paddle review by Dimitri Vandepoele - November 2023

- Win two days at Glenmore Lodge, a subscription to the Paddler and a VE paddle - September 2023

- North Sea Kayak - Raz de Sein - June 2023

News Archive

- March 2024

- December 2023

- November 2023

- September 2023

- June 2023

- May 2023

- March 2023

- February 2023

- November 2022

- August 2022

- May 2022

- March 2022

- November 2021

- June 2021

- February 2021

- December 2020

- July 2020

- April 2020

- December 2017

- July 2017

- June 2017

- May 2017

- April 2017

- February 2017

- December 2016

- November 2016

- October 2016

- September 2016

- July 2016

- June 2016

- May 2016

- April 2016

- March 2016

- February 2016

- January 2016

- December 2015

- October 2015

- September 2015

- August 2015

- July 2015

- June 2015

- February 2015

- December 2014

- November 2014

- October 2014

- September 2014

- June 2014

- May 2014

- April 2014

- January 2014

- November 2013

- September 2013

- May 2013

- April 2013

- March 2013

- February 2013

- January 2013

- December 2012

- November 2012

- October 2012