Manufacture

We make our own carbon and glass blades using hot compression moulding in a CNC-machined mould tool.

Both blades and shafts are cured under accurately controlled temperatures and pressures to guarantee quality and consistency.

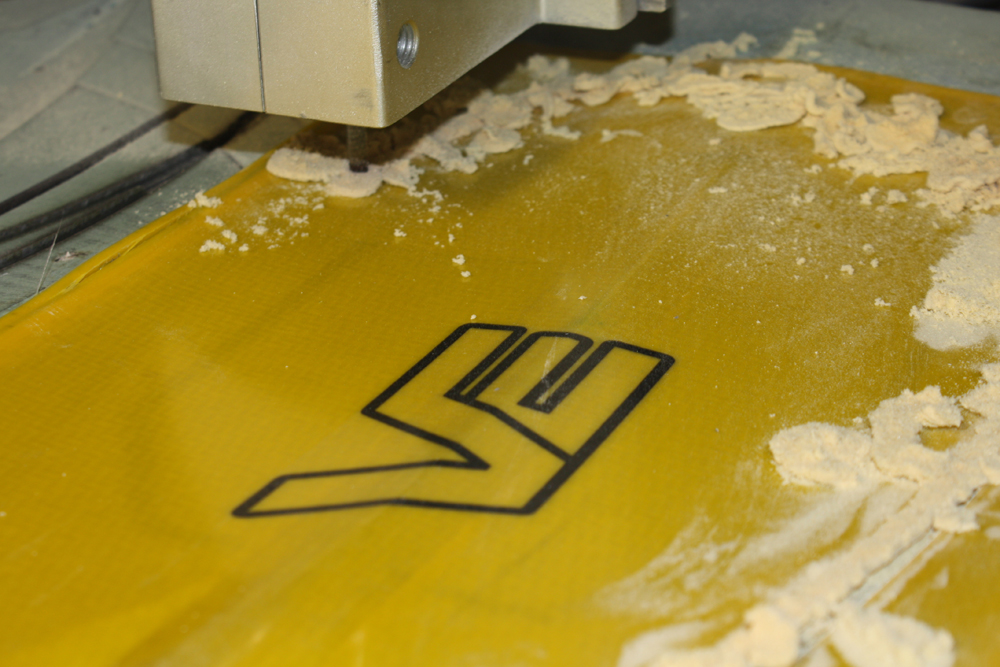

Our blades are trimmed using a CNC machine to ensure accurate and repeatable geometry.

Our straight shafts are made from either glass or carbon prepreg rolled around a mandrel and then cured at a high temperature and pressure. They are then ground to give a smooth finish and reliable grip.

Our cranked shafts are made from carbon prepreg with a high pressure bladder moulding process and CNC-machined mould.

We’re also careful about our enviromental impact. We don’t use solvents or 'volatile organic compounds' (VOCs) in any of our manufacturing processes. Also, because our blades don’t use foam cores, we don’t emit VOCs from making the cores.

We’re constantly developing and refining our manufacturing processes as new materials and technology become available.